In the high-performance footwear industry, the longevity of a sole is a critical benchmark for quality. As brands strive to deliver lighter and more comfortable products, maintaining abrasion resistance becomes a significant technical challenge. Utilizing a specialized Wear-resistant EVA sole material has become essential for manufacturers looking to enhance the durability of lightweight soles without compromising their physical properties. By integrating advanced polymer additives, factories can significantly reduce the wear value of rubber and plastic materials during high-friction activities.

For B2B procurement managers, the effectiveness of an additive is measured by empirical data. Implementing a professional wear-resistant agent—composed of an EVA carrier and silicone coupling agents—can improve the wear resistance of TPR, PCU, and EVA foaming materials by 15% to 30%. For instance, in a Wear-Resistant EVA+TPR Sport Shoe Sole, testing shows that adding just 2-5 PHR of the agent can lower the DIN wear value from 380mm³ to under 200mm³. This technical precision ensures that sports and outdoor footwear can withstand harsh terrains like rocky trails and asphalt for longer durations.

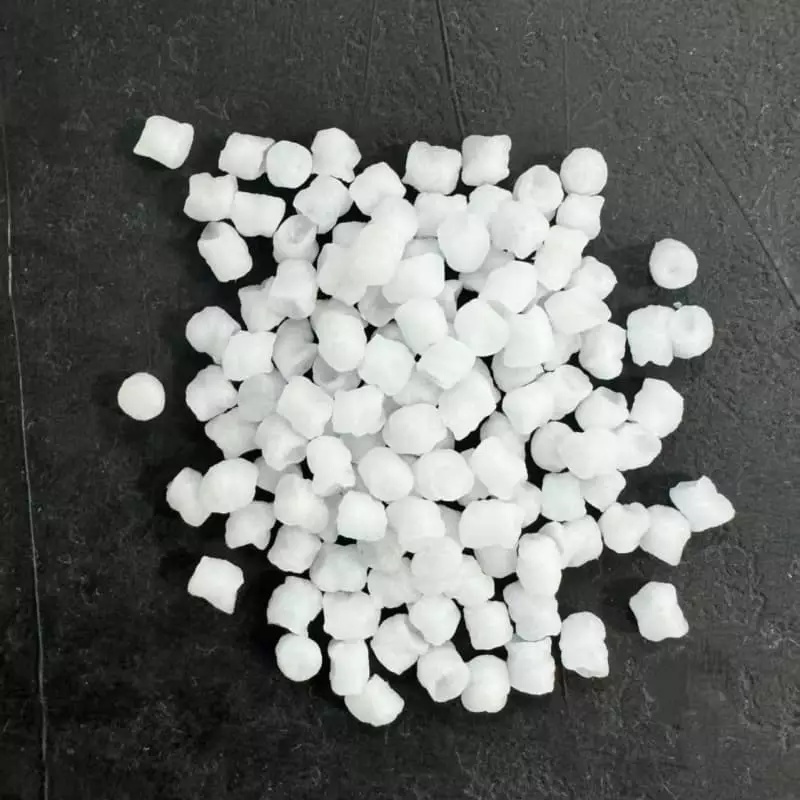

A key advantage for large-scale production lines is the ease of integration. These high-performance agents are supplied in uniform white granules, making them ideal for internal extraction and injection molding processes. Unlike external coatings, which may require a separate Release Agent for EVA Shoes Soles to ensure smooth demolding, internal wear-resistant additives become a part of the material matrix. This ensures that the finished sole maintains its light resistance, weather resistance, and ozone resistance, providing a consistent quality standard across high-volume batches.

Beyond performance, increasing the lifespan of footwear aligns with modern sustainability goals by reducing the frequency of product replacement. By utilizing a Wear-resistant EVA sole material, manufacturers can offer "premium" category products that justify higher price points through proven durability. Whether designing for casual daily wear or high-stress work environments, selecting the right polymer additives allows brands to build trust with consumers who demand footwear that performs reliably over time.

Selecting the right chemical additives is vital for balancing cost-effectiveness with high-end performance. Dongguan Yiyuan Polymer Materials provides customized formula development and technical testing to ensure your production line achieves optimal results.

Looking to enhance your product durability? Visit www.yysolematerial.com to explore our full range of additives or contact our technical team for a professional consultation.