19 December 2025

What Makes Plastic Foaming Masterbatch Oil Resistant for Shoe Soles

What Makes Plastic Foaming Masterbatch Oil Resistant for Shoe Soles

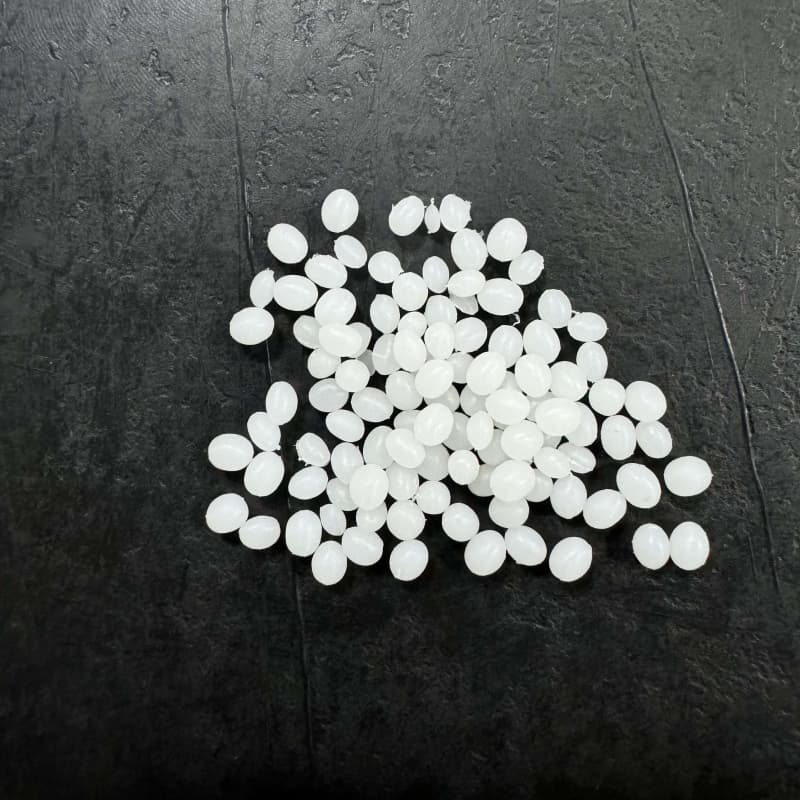

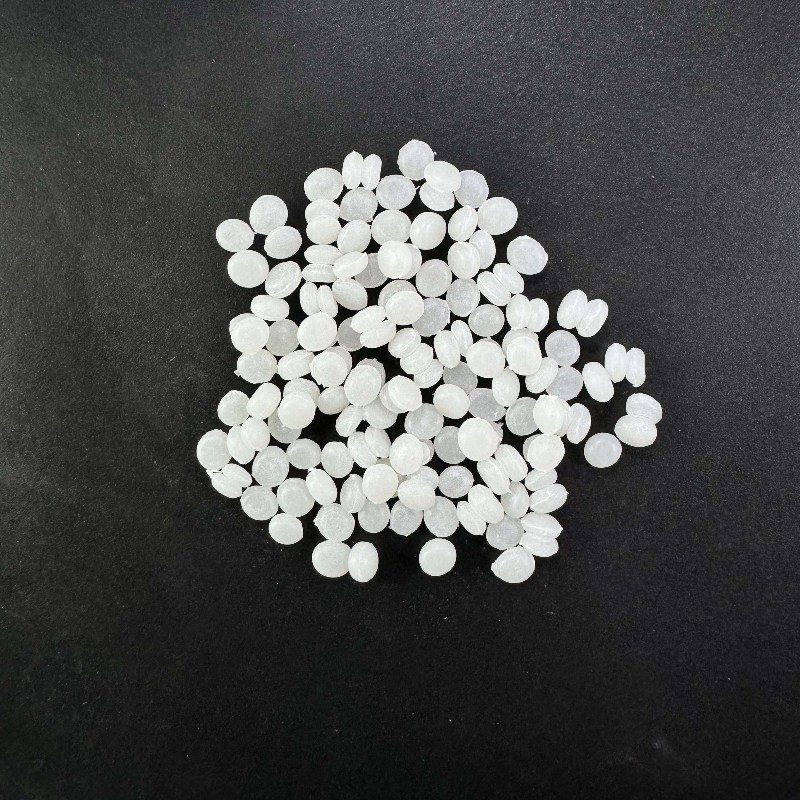

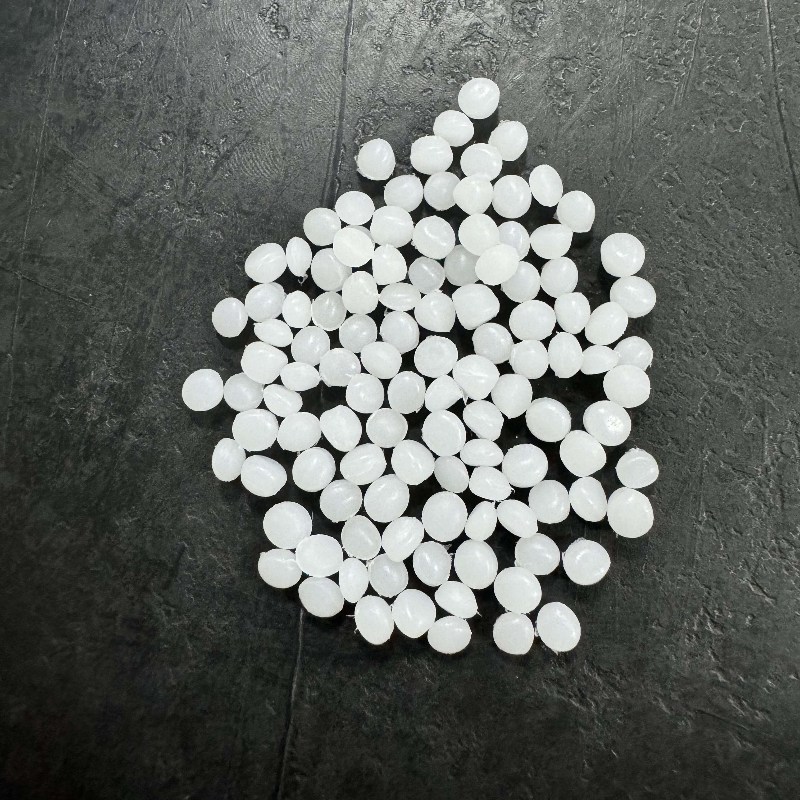

You need shoe soles that stand up to oil and keep their shape. Plastic foaming masterbatch uses high molecular polymers as carriers and blends in special additives to boost oil resistance. This smart mix helps your soles stay strong and resist swelling or breaking down in oily spots. You can use this product with EVA to make many kinds of shoes, like kitchen, mining, or factory footwear.

Key Takeaways

Plastic Foaming Masterbatch enhances shoe soles with oil resistance, preventing swelling and maintaining shape in tough environments.

Choosing the right polymer carrier is crucial for durability and oil resistance, ensuring your shoe soles last longer and perform better.

Adjusting the dosage of the masterbatch allows you to customize cushioning and strength, fitting various shoe types from kitchen to mining.

Oil resistant soles significantly reduce slip incidents, improving safety in workplaces and providing better traction on slippery surfaces.

Investing in oil resistant masterbatch saves money over time by reducing shoe repairs and replacements, leading to better overall value.

Plastic Foaming Masterbatch Features

Oil Resistant Additives

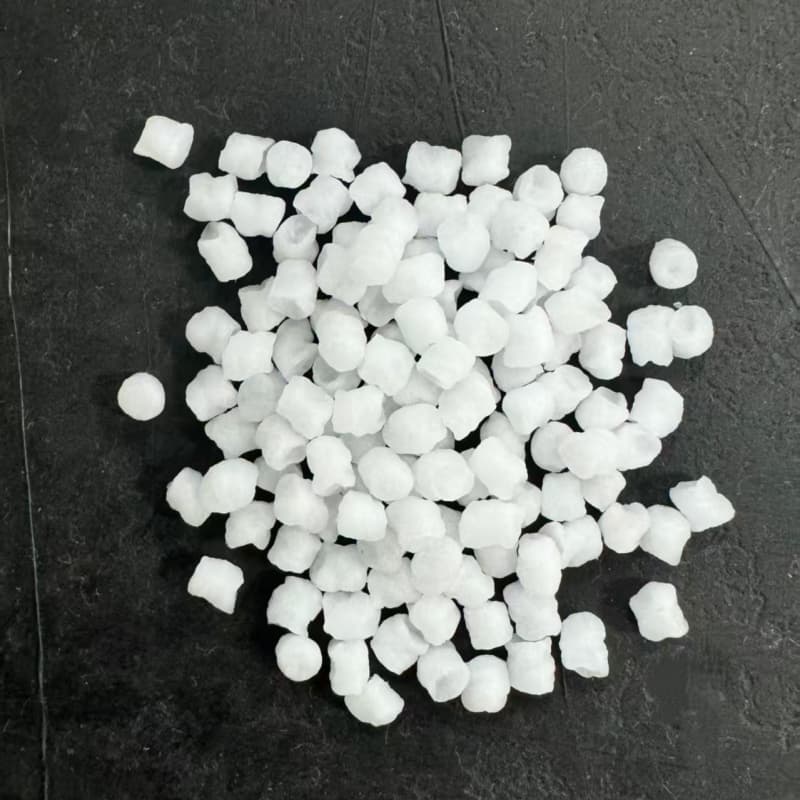

You need shoe soles that can handle tough, oily environments. Plastic foaming masterbatch uses a special blend of additives and auxiliaries to boost oil resistance. These additives work with high molecular polymers to create a strong barrier. This barrier keeps oil from soaking into the shoe sole. When you use this masterbatch, you get foamed products that stay strong and flexible, even after contact with oil. The white granule form makes it easy for you to mix into your production process. You can count on a volume swelling ratio of less than 6% after 24 hours in isooctane. This means your shoe soles will not swell or lose their shape when exposed to oil. The masterbatch also resists 903 oil, which is important for shoes used in kitchens, factories, and gas stations.

Polymer Carrier Selection

Choosing the right polymer carrier is important for both oil resistance and the strength of your shoe soles. Plastic Foaming Masterbatch uses high-quality carriers that blend well with EVA. This ensures even mixing and reliable results. You can see how different carriers affect the final product in the table below:

Polymer Carrier Type

Effect on Mechanical Properties

Effect on Oil Resistance

Fillers (e.g., talc, calcium carbonate)

Improves hardness and mechanical strength

Enhances wear resistance

Composite Polymers (e.g., TPU, EVA)

Increases strength and resilience

Improves overall durability

Wear-resistant lubricants (e.g., carbon black, PTFE)

Reduces surface friction, enhancing recovery

Increases wear resistance and longevity

When you use the right carrier, you get shoe soles that last longer and perform better in oily conditions. The masterbatch works well with EVA, so you can use it for many types of shoes.

Tip: Dongguan Yiyuan Polymer Materials Co., Ltd. offers technical support and can help you choose the best carrier for your needs. You can also ask for a custom formula to match your product goals.

Foaming Performance Optimization

Foaming performance affects how comfortable and durable your shoe soles feel. Plastic foaming masterbatch helps you get the right balance of cushioning and strength. The table below shows how foaming impacts shoe soles:

Aspect

Description

Cushioning

EVA foam gives excellent shock absorption, which reduces strain on your feet.

Durability and Weather Resistance

EVA foam is durable and stands up to tough environments, making your shoes last longer.

You can adjust the dosage of the masterbatch to get the performance you want. The recommended range is 1-5% for most EVA shoe soles, as shown here:

Dosage Range

Description

1-5%

Recommended dosage for optimal oil resistance in EVA shoe soles, depending on customer requirements.

This flexibility lets you create soles that fit different needs, from soft kitchen shoes to tough mining boots. The masterbatch’s white granule form makes it easy to measure and mix, so you get consistent results every time.

Oil Resistance Mechanism

Barrier Formation

You want your shoe soles to block oil from getting inside. Plastic Foaming Masterbatch helps you do this by creating a strong barrier. The special additives in the masterbatch mix with the polymer structure. This forms a tight network that oil cannot easily pass through. When you use this masterbatch, you make shoe soles that keep their shape and strength, even when they touch oil.

Note: A good barrier means your shoes last longer in kitchens, factories, and other oily places.

Chemical Stability

You need shoe soles that do not break down when they meet oil. The masterbatch uses high molecular polymers that stay stable in harsh conditions. These polymers do not react with oil or lose their properties. The additives also help the material resist chemical changes. This means your shoe soles stay flexible and strong, even after many hours in oily environments.

Here is a table that shows how chemical stability helps your shoe soles:

Property

Benefit for Shoe Soles

No chemical reaction

Soles do not crack or weaken

Stable structure

Soles keep their flexibility

Long-lasting strength

Shoes stay safe and comfortable

Prevention of Swelling and Degradation

You want your shoe soles to keep their size and shape. Oil can make some materials swell or break down. Plastic foaming masterbatch stops this from happening. The additives and polymers work together to prevent oil from soaking in. This keeps the volume swelling ratio low. In tests, the masterbatch showed less than 6% swelling after 24 hours in isooctane. Your shoe soles stay reliable and do not lose their form, even after long use.

You get:

Less swelling

No cracking

Longer shoe life

Benefits for Shoe Soles

Durability and Longevity

You want shoe soles that last a long time, even in tough places. When you use pastic foaming masterbatch, you help your shoes resist oil and wear. This means your soles do not crack or swell, even after many hours on the job. You will notice that your shoes need less repair and replacement. For example, kitchen shoes and mining boots often face oil and grease. With this masterbatch, these shoes stay strong and keep their shape. Factory footwear also benefits because the soles do not break down quickly. You save money and time because you do not have to replace shoes as often.

Shoes made with oil resistant materials can handle daily stress and harsh conditions. This leads to a longer product life and less maintenance.

Safety and Anti-Slip

You need shoes that keep you safe on slippery floors. Oil resistant soles help prevent slips and falls. When you add an anti slip agent to EVA shoe soles, you can see big improvements in safety. Studies show that this upgrade can reduce slip incidents by up to 70%. Lab tests and real-world trials report higher traction and better grip. Many workplaces have seen fewer accidents after switching to these materials.

Up to 70% fewer slip incidents in kitchens and factories

Higher COF (Coefficient of Friction) values in lab tests

Better traction in field tests and workplace programs

Application Versatility

You can use these oil resistant soles in many types of shoes. Kitchen shoes, mining boots, and factory footwear all benefit from the same technology. The masterbatch works well with EVA, so you can make shoes for cooks, miners, and factory workers. You can also adjust the formula to fit special needs. This flexibility means you can create shoes for many jobs and environments.

Read More

Get A Quote

Get A Quote

IPv6 network supported.

IPv6 network supported.