23 January 2026

A Comprehensive Guide to Shock Absorbing Sole Materials in 2026 Manufacturing

When selecting the best shock absorbing sole for your needs in 2026, consider Dongguan Yiyuan Polymer Materials Co., Ltd., a leading shock absorbing sole manufacturer. They recommend EVA and polyurethane as the top choices for optimal performance. The table below highlights the unique properties of these materials:

Material

Properties

Usage

EVA

Lightweight, cushions steps, absorbs impact, reduces tiredness

Midsoles in many types of shoes

Polyurethane

Denser cushion, lasts longer, feels firmer

High-end shoes, layered for comfort and strength

Shock-absorbing materials play a crucial role in workplace safety. These materials can reduce fatigue at work by up to 30%, enhancing overall productivity. Additionally, shock absorbing soles contribute to slip resistance, helping to prevent accidents and ensuring safer work environments.

Key Takeaways

Pick EVA or polyurethane for shock-absorbing soles. These materials give comfort and last a long time for many shoe types.

Think about how shock-absorbing soles help keep workers safe. They can cut down tiredness by up to 30%. This helps people work better.

Look at how much materials cost over time. EVA may cost less at first, but polyurethane lasts longer and protects feet better.

Keep learning about eco-friendly shock absorbing materials. Using recyclable choices helps make less waste and follows green rules.

Try out materials before making lots of shoes. This makes sure they are safe and work well for what you need.

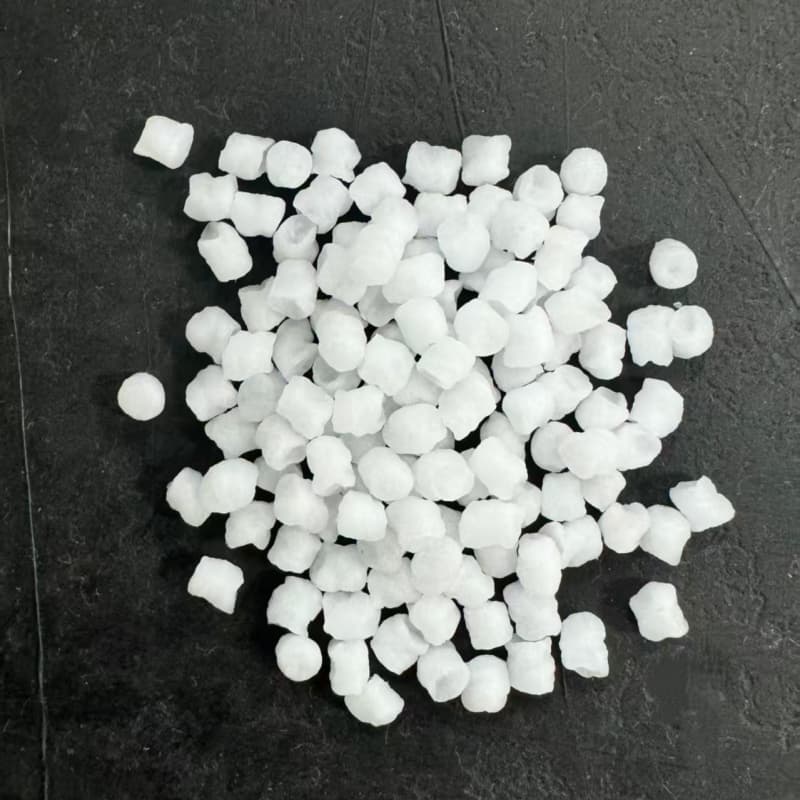

Shock Absorbing Sole Materials Overview

Image Source: pexels

What Are Shock Absorbing Soles?

You might ask how shock absorbing soles are different. These soles use special compounds to lower the force when you walk. They help protect your feet and joints by spreading out the impact. In factories, workers need soles that can handle hard work and keep them comfy all day.

Many shock-absorbing materials have special features:

TPE compounds feel very soft and give more comfort.

You can shape these materials in many ways and colors.

They do not get damaged by chemicals or rough surfaces.

Some materials help stop slips, which keeps workers safe.

Flexibility, grip, weight, and how long they last are important. These things help you pick the best material for your job.

Importance in Manufacturing

In factories, it is hard to pick the right shock absorbing sole. You want soles that last and keep workers safe. Shoes that resist wearing out last longer and wear evenly. It is also important that the material always works the same way. This helps keep customers happy and protects your company’s name.

Dongguan Yiyuan Polymer Materials Co., Ltd. has strong technical skills and is ready for factory use. The table below shows how they compare to other companies:

Supplier

Strengths in Material Innovation

Dongguan Yiyuan

Technical performance, industrial application readiness

Shanxi Bondx

Leading in material innovation

Jiangxi Gooz

Leading in material innovation

GUJRAL INDUSTRIES

Unmatched value for large-scale structural repairs

Always choose shock-absorbing materials that fit your workplace needs. These materials help keep workers safe and comfortable. They also help you work better and save money in your factory.

How Shock-Absorbing Materials Work

Impact Absorption Science

When you walk or stand on hard floors, your body feels impact forces. In factories, these forces can be much stronger. They can be 1.5 to 3 times your body weight with each step. Your foot’s arches help with these forces. But standing for a long time on concrete or steel is tough. Your body’s shock absorption can get tired. That is why you need help from shock absorbing soles. These soles spread out the force and protect your joints. They also keep you comfortable. Good shock absorption helps your muscles work better. It lowers your chance of getting hurt or tired.

Manufacturers use tests to see how well a sole absorbs shock. The table below lists some common lab tests:

Test Type

Description

Impact Test

Measures a shoe's potential to absorb impact and protect the wearer's foot from sudden shocks.

Compression Test

Compares different structures and materials for insoles and midsoles, assessing how they perform under pressure.

Dynamic Shock Absorption Test

Evaluates cushioning properties by measuring the impact peak acceleration of different insoles.

Energy Dissipation in Manufacturing

You want soles that do more than just absorb shock. They should also handle energy well. Energy dissipation means the material takes the force from your step and turns it into heat. This way, less force goes up your leg. Scientists use Dynamic Mechanical Analysis (DMA) to check this. They look at numbers like loss modulus and tan δ. If tan δ is higher, the material absorbs more energy. This gives you better protection.

DMA checks how well a material stops vibrations.

Loss modulus and tan δ show how much energy the sole can take in and change.

When you put more strain on cross-linked elastomers, energy dissipation goes up. For example, damping capacity can rise from 66% to 93% as strain increases.

Real shoe designs show how much energy you can save with the right sole. The chart below compares different midsoles and outsoles:

You can see that midsoles with special shapes, like re-entrant auxetic shapes or round holes, absorb over 150% more energy. This means you get more comfort and safety in tough factory jobs.

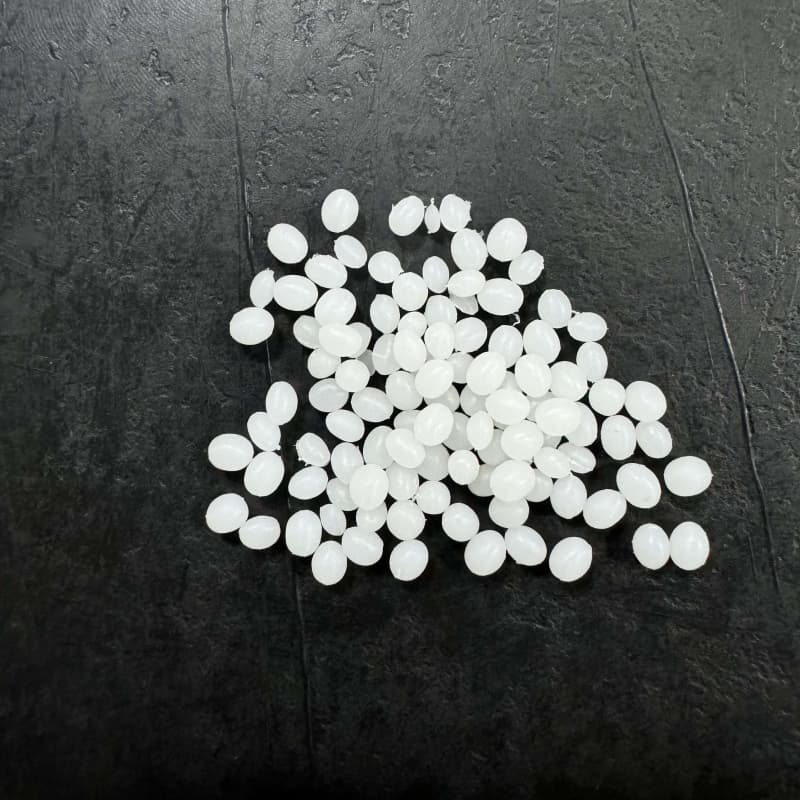

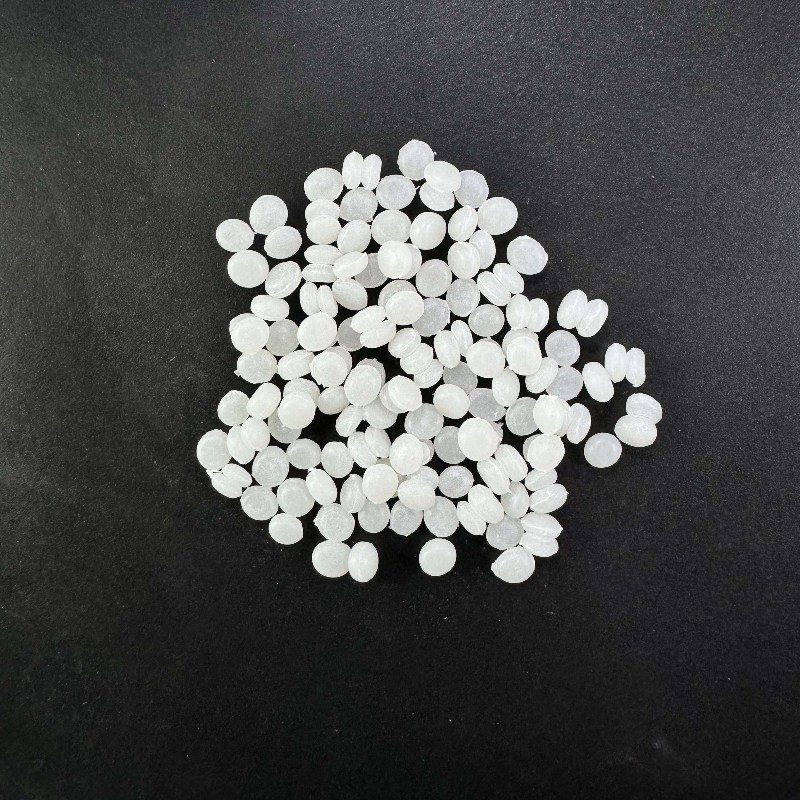

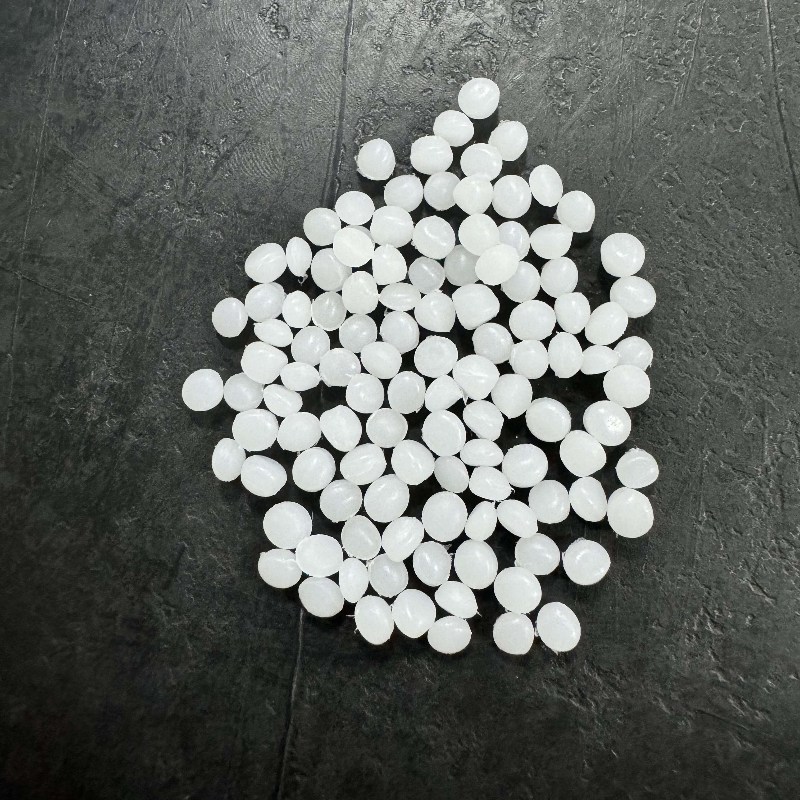

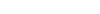

Comparing Shock Absorbing Foam and Sole Materials

Image Source: pexels

EVA, PU, and TPU Foams

There are many kinds of shock absorbing foam used today. EVA, PU, and TPU foams are the most common in factories. Each one has special features for making soles.

EVA stands for ethylene vinyl acetate. It makes soles that are light and bend easily. You see EVA in running shoes and everyday sneakers. It helps cushion your feet and takes in impact well. PU means polyurethane. It is strong and lasts a long time. PU is great at absorbing shocks. You find PU in work boots and sports shoes. TPU is short for thermoplastic polyurethane. It is very tough and does not wear out fast. TPU is best for shoes that need to be strong and safe.

Here is a table that shows how these foams compare:

Foam Type

Shock Absorption

Durability

Energy Return

Applications

EVA

Good

High

60-65%

Daily trainers, running shoes

PU

Excellent

Very High

Moderate

Work boots, athletic footwear

TPU

High

Premium

High

High-performance shoes, safety footwear

Each foam works best for different things. EVA is good for comfort and bending. PU gives you shoes that last longer. TPU is best for hard jobs and top performance.

You should also think about how long the foam lasts. TPU is very stretchy, does not wear down, and handles weather well. EVA is also stretchy and stands up to weather. PU is known for being light and soaking up shocks. These things help you pick the right foam for your factory.

Gel and Hybrid Composites

Gel and hybrid composites are changing how we make shock-absorbing soles. Shear stiffening gel, or SSG, is very good at stopping shocks. This gel is soft when you walk slowly. It gets hard if you move fast, so it protects you from sudden hits. Old foams like PU and EVA only give basic protection. They do not take in as much energy as gel does.

Hybrid composites mix different materials together. This makes them better at giving back energy and feeling comfy. These materials are good for keeping both products and machines safe. Gel and hybrid systems are best where safety is very important.

Here is a table to show how gel and hybrid composites are different from old foams:

Material Type

Shock Absorption Capability

Additional Properties

Shear Stiffening Gel (SSG)

Superior

Strain-rate-sensitive hardening, flexible at low strain rates, rigid during high-speed impacts

Traditional Foams (PU, EVA)

Limited

Passive protection, low energy absorption capacity, flammability issues

You can use gel and hybrid composites for new types of shock absorbing soles. These materials give you more ways to protect feet and equipment.

Pros and Cons for Manufacturing

You need to look at the good and bad sides of each foam before picking one. EVA is easy to make and does not waste much material. PU is light, comfy, and does not get ruined by air. TPU is very strong and looks nice.

Here is a table to help you see the good and bad points:

Foam Type

Advantages

Disadvantages

EVA

High production efficiency, No edge waste, Almost no material loss

Lower production efficiency, High energy consumption, Significant impact of process conditions

PU

Lightweight, Good oxidation resistance, Shock-absorbing

Absorbs water easily, Poor durability, Prone to yellowing

TPU

High mechanical strength, Premium appearance

Poor heat resistance, Tends to yellow during processing

You should also think about the environment. Shoe companies now want to use materials that can be recycled or are made from plants. Most companies check how much carbon their products use. TPE is a kind of foam that can be recycled again and again. Old shoes or scraps can be used to make new products. This helps cut down on trash and is better for the planet.

Tip: Using recyclable shock-absorbing materials helps your company follow new rules. It is now very important to think about the environment when making shoes.

Recycling can be hard. Many soles use lots of different plastics and glues. Less than 10% of shoe waste gets recycled around the world. This makes it tough to reuse old shoes. New plant-based plastics may help lower the carbon footprint of shoe materials.

When you pick a shock absorbing sole, think about how well it works, how long it lasts, and how it affects the earth. Each material has its own good points for safety, comfort, and protection. You can choose the best foam for your needs and your factory.

Selecting the Right Shock Absorbing Sole for Manufacturing

Key Criteria: Durability, Comfort, Cost

When you pick shock-absorbing materials for your factory, you should think about three things. These are durability, comfort, and cost. Each one changes how safe and good your shoes are. You want workers to feel safe and comfy all day. You also want your shoes to last a long time.

Rubber and PU can cost more at first. But they last longer and protect feet better. These materials do not wear out fast, so you do not need new shoes often.

EVA soles are cheaper when you buy them. But they wear out faster. This means you might spend more money later because you need to replace them more.

The material you choose will change how comfy and strong your shoes are. Good materials help you make customers happy and keep your company’s good name.

You should always test your materials before making lots of shoes. Testing helps you know if the shock-absorbing materials work well in real life.

You should also think about the planet. Many companies want materials that are easy to recycle or come from green sources. This helps you make less trash and keep the earth clean.

Application Fit and Trends for 2026

You need to pick shock-absorbing materials that fit your factory’s needs. Every job has different rules for safety and how well shoes must work. In 2026, new trends will change how you pick materials.

Smart factories use IoT and real-time data to watch materials and make them better. This helps you find problems early and keep shoes safe.

Automation and robots help make shock-absorbing materials with less waste and fewer mistakes.

Customization lets you make soles for special needs, like extra safety or better for the planet.

Digital tools help you follow your materials from start to finish. This makes it easier to pick green options.

Machine learning and sensors help you find problems before they get big.

You should not make common mistakes. Do not think all imported materials are always good. Do not forget to store and handle materials the right way. Always check the warranty and return rules to protect your money.

If you think about durability, comfort, cost, and the planet, you can pick shock-absorbing materials that keep workers safe and help your business do well.

You should look for new shock absorbing sole materials. These help your factory stay safe and work well. New materials make shoes lighter. This helps workers move faster and feel better. Using easy-to-recycle materials helps the planet too.

Lighter soles help workers move quickly.

Safer shoes keep workers from getting hurt.

Recycling more means less trash in factories.

Key Takeaway

Description

Emerging Applications and Material Innovation

Pick smart, eco-friendly, and strong materials for shoes.

Sustainability and ESG Shifts

Use low-carbon materials to follow rules and please customers.

Strategic Recommendations

Make green materials and use digital tools for better shoes.

Learn about new trends so your business stays ahead.

FAQ

What is the best shock absorbing sole material for heavy-duty manufacturing?

Polyurethane is a good choice for heavy-duty jobs. It lasts a long time and absorbs shocks well. This material works in tough factories. It helps keep your feet safe during long work hours.

How do I know if a sole material is safe for my workers?

Check if the material has safety certificates and test results. Make sure it passes impact and slip tests. Good suppliers will share this information with you. Always ask for proof before you buy anything.

Can shock absorbing soles help reduce worker fatigue?

Yes, these soles lower the force on your feet and joints. You will not feel as tired after standing for a long time. This makes you more comfortable and helps you work better.

Are eco-friendly shock absorbing materials available?

There are green choices like recycled TPE and plant-based foams. These materials help cut down on waste and protect the earth. Ask your supplier about eco-friendly options for your factory.

Read More

Get A Quote

Get A Quote

IPv6 network supported.

IPv6 network supported.