You want a wear-resistant agent that keeps sport shoe soles strong in 2025. Silicone wear-resistant agent is special. It gives up to 70% better wear-resistant strength. It helps soles last longer. This wear-resistant agent works with EVA, TPR, and PVC. It gives durability, flexibility, and eco-friendly benefits. The silicone wear-resistant agent protects your wear-resistant shoe soles. The wear-resistant agent also keeps comfort. As the market grows, you need a silicone wear-resistant agent that does well in every wear-resistant test.

A wear-resistant agent helps protect shoe soles from getting worn out. It acts like a shield and keeps soles strong when you walk or run on rough ground. If you add a silicone wear-resistant agent to EVA, TPR, or PVC, the soles become tougher. The agent mixes deep into the materials and makes them last longer. EVA wear-resistant agent is great for sport shoe soles. It helps them stay in shape and keeps them strong. Without a wear-resistant agent, most EVA soles do not last long enough. EVA soles without additives can wear down by about 450 mm³. With a silicone wear-resistant agent, this goes down to 135 mm³. Your shoes get better protection and last longer.

When you choose a wear-resistant agent for 2025, you need more than just protection from wear. You want comfort, safety, and good performance. Look for these important features:

| Chemical Property | Benefit |

|---|---|

| Durability | Makes shoe soles last much longer |

| Slip resistance | Keeps you safe and comfortable |

| Surface hardness | Stops scratches on the soles |

| Flexibility and elasticity | Helps shoes feel good and work well |

| Reduced production waste | Less material gets thrown away |

| Decreased maintenance | Shoes need fewer repairs |

Silicone wear-resistant agent gives you many good things. It mixes with EVA, TPR, and PVC to make soles stronger and easier to bend. Your shoes last longer and do not wear out fast, even on rough ground. Silicone wear-resistant agent also makes shoes more comfortable and helps you move better. It lowers pressure on your feet so you do not feel pain when you play sports or walk a lot. Silicone wear-resistant agent is good for the planet too. It helps make less waste and lowers costs when making shoes. Manufacturers say they throw away 40% less material and spend 15-20% less money after using silicone wear-resistant agent. You get shoes that are high quality, work well, and are better for the environment.

You want your sport shoe soles to last longer. Reliable eva wear-resistant agents help with this. These agents work with many foaming materials. They work with EVA, TPR, and PVC. Silicone wear-resistant agent gives high din abrasion resistance. It also makes the soles more durable. The agent mixes into the eva and makes a smooth surface. This surface does not wear out fast. You see fewer defects and flaws as time goes on.

Here is a table that lists the main features of reliable eva wear-resistant agents:

| Feature | Description |

|---|---|

| Lightweight | Lighter than traditional rubber soles, improving comfort. |

| Flexibility | Adapts to various foot shapes for better fit and comfort. |

| Wear resistance | Smooth surface that is not easily worn, ensuring a long service life. |

| Oil resistance | Specially treated to resist oil and water stains, maintaining cleanliness. |

| Anti-aging | Good anti-oxidation performance, maintaining quality over time. |

| Application | Xiangxi's silicone masterbatch enhances wear resistance and performance. |

You notice better abrasion resistance with these agents. EVA soles with anti-abrasion silicone lose less than 100 mg in the DIN Abrasion Test. Regular EVA soles lose 300-500 mg. Silicone wear-resistant agent helps improve din abrasion values. It also reduces surface flaws. Shoes with these agents last over 12 months. Regular soles wear out in only 3 months.

You can use eva wear-resistant agent with TPR and PVC soles. This gives better performance. Silicone wear-resistant agent mixes well with these materials. It is easy to use and stands up to heat during production. You add the anti-wear agent while making the soles. This boosts wear-resistant properties. You can use melt blending methods. These include single or twin screw extruders and injection molding. These ways help you get good results every time.

Here are some tips for using eva wear-resistant agent:

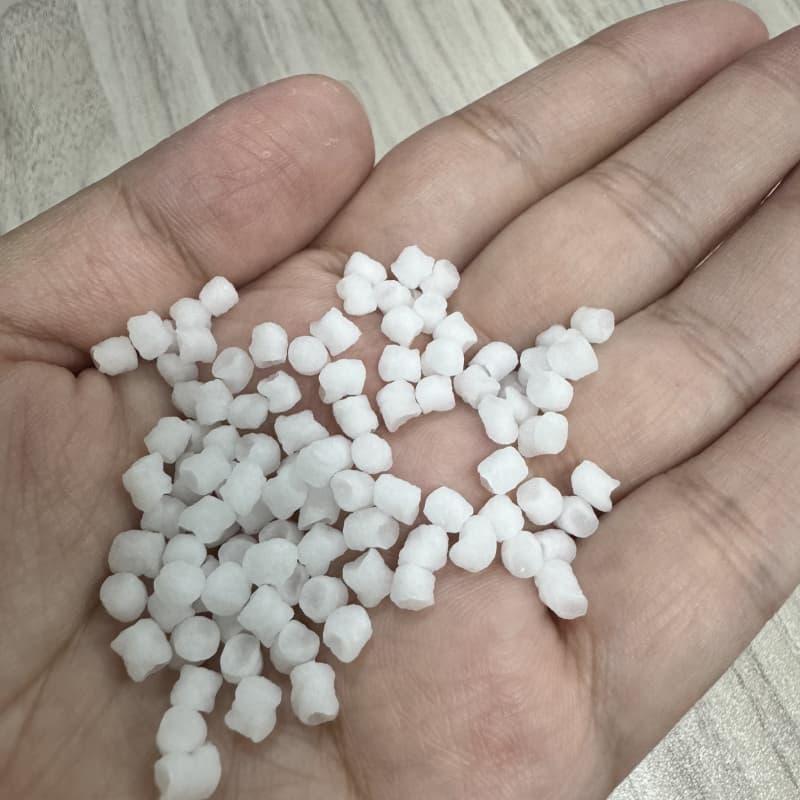

EVA wear-resistant agent works well with TPR and PVC. This makes the final product better. You get more abrasion resistance without changing hardness or color. The anti-abrasion masterbatch NM-2T has 50% UHMW Siloxane polymer in EVA resin. This mix helps lower abrasion value and keeps the surface looking good. You see fewer defects and better production speed.

| Feature | Description |

|---|---|

| Product Name | Anti-abrasion masterbatch NM-2T |

| Composition | 50% UHMW Siloxane polymer dispersed in EVA resin |

| Purpose | Improves abrasion resistance and decreases abrasion value in thermoplastics |

| Advantages | Better abrasion resistance without affecting hardness and color compared to conventional additives |