Wear-resistant agent is a kind of polymer material made by blending EVA as carrier, silicone coupling agent as main component and active agent. It can reduce the wear of rubber and plastic materials. It will not affect the light resistance, weather resistance, ozone resistance and other physical properties of rubber and plastic materials. Wear-resistant agent is most suitable for TPR, PCU (PVC physical foaming), EVA foaming and other foaming materials.

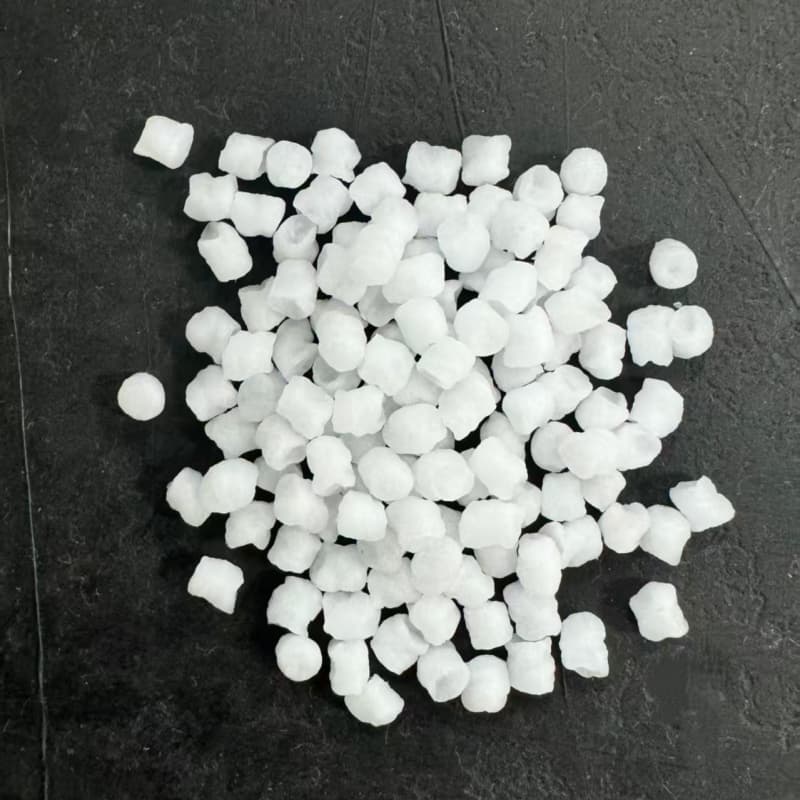

Appearance :

White uniform granulesNet weight :

25KG/bagExperimental Data:

| Test items | Specific gravity (g/cm3) | AKRON wear value (mm3) | NBS wear ratio (%) | DIN wear value |

| TPR | 0.95-1.05 | 0.33-0.36 | 45-55 | 320-380 |

| TPR+2PHR | 0.95-1.05 | 0.22-0.25 | 60-75 | 200 or less |

| PCU | 0.65-0.75 | 0.38-0.42 | 35-45 | 360-420 |

| PCU+2PHR | 0.65-0.75 | 0.26-0.32 | 60-65 | 220-260 |

| EVA foam | 0.15-0.22 | 0.32-0.38 | 25-40 | 280-330 |

| EVA foam + 5PHR | Ratio 150 | Hardness 50C | 70-85 | 150 or less |

Conclusion:

Summary: Adding 2-5PHR to TPR, PCU (PVU physical foaming) and EVA foaming can increase the wear resistance by 15-30% (AKRON, NBS, DIN)

TPR test formula (TPE475: 60/PS: 20/EVA: 3/HDPE: 3/white smoke: 8/stone powder: 20/softening oil: 18/stearic acid: 0.2)

PCU test formula (PVC: 100/DINP: 80/stable agent, lubricant and other additives, expansion agent 1%)

EVA test formula (EVA: 100, foaming agent: 3, DCP: 0.5, lubricant: 2, stone powder 5-10)

The above data and information are for reference only, and the specific conditions depend on the customer's machine conditions, processing conditions, and mold structure.

Application Scenarios:

Sports And Running Shoes: reduceing sole wear from frequent friction, extending shoe lifespan

Outdoor And Hiking Footwear: improves resistance to rough surfaces like asphalt, trails, and rocky terrain

Casual And Work Shoes: enhancing longevity for daily wear, particularly in high-stress areas like heels and forefoot

Foam-Based Footwear: ideal for lightweight EVA or PVC foam soles that require better abrasion resistance

Instructions for use:

Storage conditions:

Keep in a dry and cool place, avoid direct sunlight, and the room temperature should not exceed 50℃ to avoid adhesion of particles. Please avoid fire and heat sources.

Under normal circumstances, the product is properly stored in the original sealed packaging, and the recommended shelf life is 2 years.

Why Choose Us

Customized formula development

Customized formula development

Technical support and testing services

Technical support and testing services

After-sales problem solving

After-sales problem solving

Assist in improving the surface gloss or touch of finished products

Analyze processing abnormalities and provide solutions.

About Us:

|

|

|

|

Dongguan Yiyuan Polymer Materials Co., Ltd. is a company that integrates R&D, production, processing, sales of polymer plastic elastomer materials, plastic modified raw materials, plastic products, and sales of other chemical products (excluding hazardous chemicals): import and export of goods or technology (except for goods and technology import and export prohibited by the state or involving administrative approval).

The company is deeply engaged in professional fields, customer-oriented, and is committed to the modification and solution provision of rubber and plastic raw materials. It advocates reducing the burden on the earth and promoting the recycling of environmentally friendly new materials. Yiyuan provides customers with raw material application technology services, including raw material testing, formula design, product testing, and solving problems in the raw material application process.

Since its establishment, it has invested in the construction of a technical research and development system and established a testing and analysis laboratory. It has independently developed functional materials such as high-elastic particles, lightweight high-elastic particles, ethylene elastomers, thermoplastic elastomers, spot removers, wear resistant agents, shock-absorbing masterbatches, shrinkage stoppers, GRS certified materials, and bio-based certified materials.