This foaming masterbatch has a bio-based content of more than 95%, and has obtained the US BETA laboratory test certification. It is an environmentally friendly polymer material that aims to provide high-quality foaming solutions for various plastic products. It uses advanced production technology to perfectly combine bio-based materials with high-efficiency foaming agents and other functional additives, which not only ensures the high performance of the product, but also complies with the environmental protection concept of sustainable development.

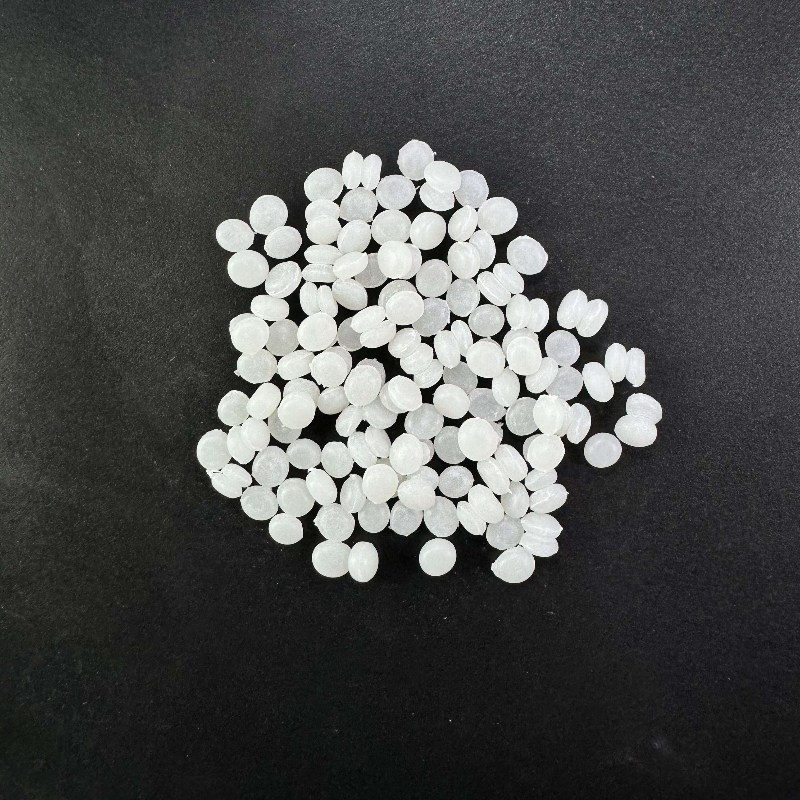

Appearance :

White uniform granulesExperimental Data:

| Property | Typical Value | Test Method / Standard |

| Appearance | White pellets | Visual Inspection |

| Bio-based Content | ≥ 95% | Certified by BETA Laboratory |

| Carrier Resin | EVA / POE | / |

| Foaming Performance | Uniform foam, fine cell structure, good elasticity | Internal Lab Test |

| Foaming Temp. Range | 160°C – 190°C | Processing Recommendation |

| Environmental Compliance | RoHS / REACH compliant, non-toxic | SGS / Third-party certification |

| Recommended Dosage | 5% – 15%, adjustable as needed | Depends on application |

| Compatible Materials | EVA, POE, biodegradable resins | / |

| Storage Conditions | Store in a dry, cool place, avoid direct sunlight | / |

| Shelf Life | 12 months (unopened) | / |

Conclusion:

High bio-based content: Bio-based ingredients account for more than 95%, significantly reducing dependence on traditional energy sources such as oil, reducing carbon emissions, and promoting sustainable development.

Excellent foaming performance: good elasticity, stable foaming ratio, can produce uniform and delicate pore structure.

Environmental protection and safety: does not contain harmful substances, meets relevant environmental protection standards, is environmentally friendly, and harmless to human health.

Strong processing adaptability: The foaming temperature range is wide and can be adjusted freely between 160℃ - 190℃, suitable for various foaming processes

Application Scenarios:

Suitable for:

Eco-friendly Footwear Soles

Lightweight, cushioned soles made from EVA/POE blends for casual shoes, sandals, and biodegradable work footwear.

Bioplastic Packaging

Used in thermoformed packaging or protective foam trays that require both structural integrity and environmental compliance.

Sustainable Consumer Products

Applicable in foamed parts of sporting goods, yoga blocks, household items, and other everyday plastic products where sustainability is a key consideration.

Green Construction Materials

Used as an additive in foamed insulation boards, underlayment materials, or wall panels with reduced carbon footprint.

Usage method

Addition amount: According to the customer's requirements for bio-based content, it can be added with EVA, POE and other materials at will

Compatible Materials

EVA (Ethylene-vinyl acetate)

POE (Polyolefin elastomer)

Other bio-based or recyclable polymers

Recommended Processing

Processing Temperature: 160°C – 190°C

Foaming Method: Injection molding, compression molding, or extrusion

Recommended Dosage: To be adjusted according to required bio-content and product design

Why Choose Us

Customized formula development

Customized formula development

Technical support and testing services

Technical support and testing services

After-sales problem solving

After-sales problem solving

Assist in improving the surface gloss or touch of finished products

Analyze processing abnormalities and provide solutions.

About Us:

|

|

|

|

Dongguan Yiyuan Polymer Materials Co., Ltd. is a company that integrates R&D, production, processing, sales of polymer plastic elastomer materials, plastic modified raw materials, plastic products, and sales of other chemical products (excluding hazardous chemicals): import and export of goods or technology (except for goods and technology import and export prohibited by the state or involving administrative approval).

The company is deeply engaged in professional fields, customer-oriented, and is committed to the modification and solution provision of rubber and plastic raw materials. It advocates reducing the burden on the earth and promoting the recycling of environmentally friendly new materials. Yiyuan provides customers with raw material application technology services, including raw material testing, formula design, product testing, and solving problems in the raw material application process.

Since its establishment, it has invested in the construction of a technical research and development system and established a testing and analysis laboratory. It has independently developed functional materials such as high-elastic particles, lightweight high-elastic particles, ethylene elastomers, thermoplastic elastomers, spot removers, wear resistant agents, shock-absorbing masterbatches, shrinkage stoppers, GRS certified materials, and bio-based certified materials.