GL-70 TPE Thermoplastic Elastomer is a thermoplastic elastomer composite material developed and produced by YIYUAN, designed for midsole foaming applications. It uses ethylene-based block copolymers as the base material, with excellent rebound performance, ultra-light texture and processing convenience. GL-70 TPE Thermoplastic Elastomer has been widely used in the manufacture of small foam midsoles. It can be efficiently produced through general EVA foaming processing methods and is suitable for mid-to-high-end footwear products that require light weight, high elasticity and high support.

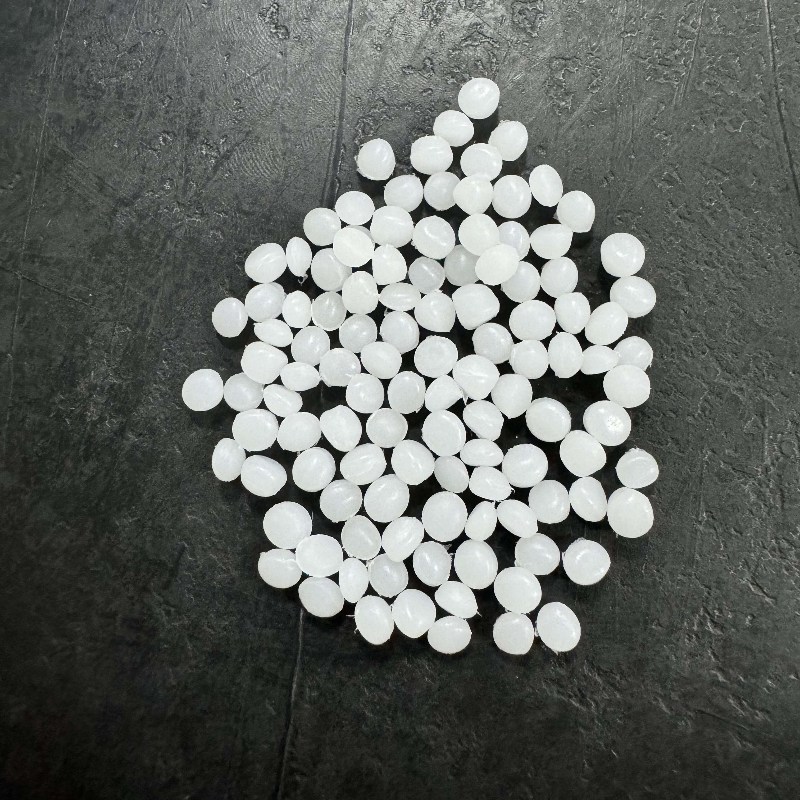

The product is supplied in the form of granules, which is convenient for molding using various types of automated or semi-automated equipment. It is an ideal choice for sports shoes, casual shoes and functional sole materials.

Item No :

GL-70Appearance :

White uniform granulesExperimental Data:

|

PROPERTIES |

TESTING METHOD |

CONDITIONS |

UNITS |

VALUES |

|

Product Form |

N/A |

-- |

-- |

Granular |

|

Color |

N/A |

-- |

-- |

Natural |

|

Shore hardness |

ASTM D2240 |

A Type |

Shore A |

90 |

|

Flow index |

ASTM D1238 |

180℃*5 kg |

g/10min |

1-5 |

|

Specific gravity |

ASTM D792 |

-- |

-- |

0.88 |

|

Tensile strength |

ASTM D412 |

Type3, specimen |

kg/cm2 |

65 |

|

Elongation |

ASTM D412 |

Crosshead |

% |

650 |

|

300% modulus |

ASTM D412 |

500mm/min |

kg/cm2 |

25 |

|

Tear strength |

ASTM D624 |

C Die |

kg/cm |

25 |

Conclusion:

GL-70 High Rebound TPE Thermoplastic Elastomer has a low specific gravity of only 0.88, which can effectively reduce the overall weight of the sole. At the same time, its elongation of up to 650% and tensile strength of 65 kg/cm² ensure that the finished sole still maintains excellent elasticity and lasting support during high-frequency sports.

This product is designed for small foaming and is still easy to control under high-rate foaming, ensuring uniform pores and stable structure. It can seamlessly replace traditional EVA materials and adapt to existing EVA foaming production lines without major equipment adjustments.

Shore A hardness of 90 provides good support

300% modulus is only 25 kg/cm², soft and firm, comfortable and non-slumping

Tear strength is as high as 25 kg/cm, improving the overall durability of the sole

GL-70 Thermoplastic Elastomer is supplied in granules, which can be recycled and reused, in line with the trend of sustainable manufacturing, easy to measure, transport and automatically feed, compatible with mainstream thermoplastic elastomer processing technology, and suitable for batch continuous production.

Application Scenarios:

Midsole foaming materials (sports shoes, casual shoes, outdoor shoes, etc.)

High-elastic cushion and support structure

Other molded parts that require both lightness and elasticity

Molding Processing Technology

Material Drying:

Store under normal dry storage conditions and avoid direct sunlight.

Molding Method:

The following are some of our processing suggestions and guidelines for foam molding, but in actual operation, past processing experience should be used as the main basis.

Generally, 100% can be added for midsole foaming, and EVA or POE can be added at will according to customer requirements.

Others:

Compression molding conditions are about 70 seconds at 170℃ and 1 mm thick

The test method of the above physical property data is measured with reference to the ASTM procedure, and all test pieces are made by injection molding; the description of this technical data does not provide patent authorization, sales and health guarantee for product use.

Why Choose Us:

Community charging overall solution covers all application

Customized formula development

Customized formula development

Technical support and testing services

Technical support and testing services

After-sales problem solving

After-sales problem solving

Assist in improving the surface gloss or touch of finished products

Analyze processing abnormalities and provide solutions.

About Us:

|

|

|

|

Dongguan Yiyuan Polymer Materials Co., Ltd. is a company that integrates R&D, production, processing, sales of polymer plastic elastomer materials, plastic modified raw materials, plastic products, and sales of other chemical products (excluding hazardous chemicals): import and export of goods or technology (except for goods and technology import and export prohibited by the state or involving administrative approval).

The company is deeply engaged in professional fields, customer-oriented, and is committed to the modification and solution provision of rubber and plastic raw materials. It advocates reducing the burden on the earth and promoting the recycling of environmentally friendly new materials. Yiyuan provides customers with raw material application technology services, including raw material testing, formula design, product testing, and solving problems in the raw material application process.

Since its establishment, it has invested in the construction of a technical research and development system and established a testing and analysis laboratory. It has independently developed functional materials such as high-elastic particles, lightweight high-elastic particles, ethylene elastomers, thermoplastic elastomers, spot removers, wear resistant agents, shock-absorbing masterbatches, shrinkage stoppers, GRS certified materials, and bio-based certified materials.