Shrinkage-stopping masterbatch ZS1001 is a high-quality polymer composite material designed to enhance the performance of foamed products. It provides excellent elasticity while effectively reducing shrinkage during and after the foaming process, ensuring dimensional stability and improved product quality. This masterbatch is ideal for applications requiring both flexibility and minimal deformation, making it suitable for industries such as footwear, packaging, and automotive interiors.

Item No :

Shrinkage-stoping masterbatchColor :

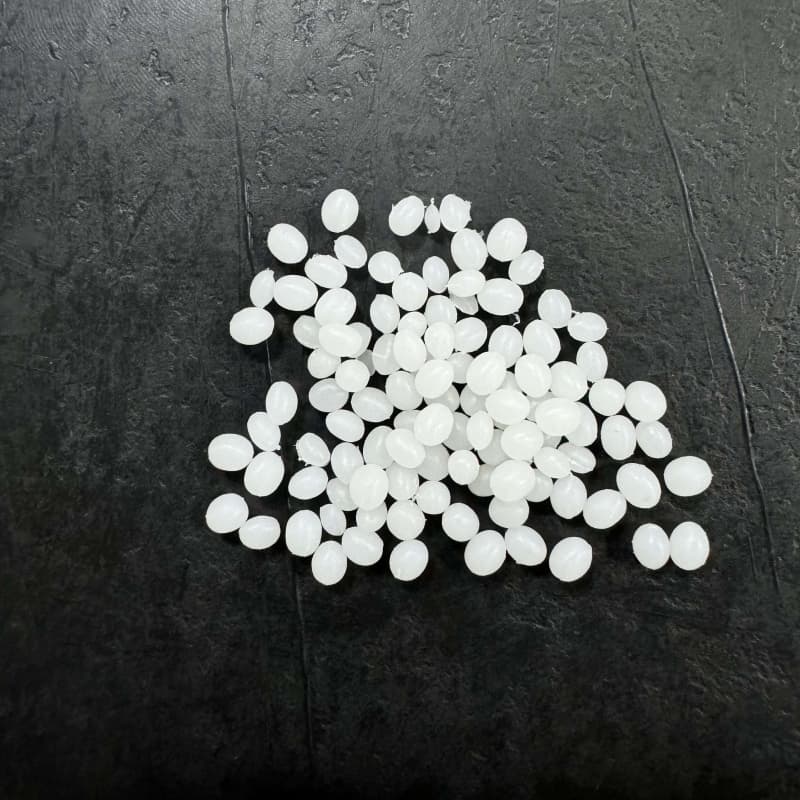

NaturalAppearance :

GranularAvailable in convenient granular form with a natural color, ZS1001 is easy to handle and blend with various polymer matrices. Each batch is securely packaged in durable, waterproof paper bags, with a standard weight of 25KG per bag to ensure safe storage and transportation. Its reliable performance and user-friendly form make it an essential additive for manufacturers seeking superior foam products with reduced shrinkage and maintained elasticity.

Effective Shrinkage Control: Adding 10-15% ZS1001 to EVA foam significantly reduces post-foaming shrinkage. Maintains a stable hot growth to cold growth ratio, limiting dimensional variation to ~10mm.

Enhanced Elasticity & Stability: Balances elasticity and anti-shrinkage properties, preventing deformation while keeping flexibility. Ideal for footwear, sports mats and packaging foam parts.

Easy Processing & Compatibility: Granular form (natural color) ensures uniform mixing with EVA and other polymers. Works seamlessly in standard foaming processes without requiring special equipment.

Convenient Packaging: Packed in 25KG waterproof paper bags for moisture resistance and safe storage/transport.

Consistent & Reliable Performance: Improves foam product uniformity, reducing waste and enhancing production efficiency. Suitable for both hot and cold foaming applications.

Application Scenarios:

Direct Replacement for High-Cost Alternatives:

Seamless Integration Without Process Changes:

Performance Comparable to OBC INFUSE:

Storage conditions:

Keep in a dry and cool place, avoid direct sunlight, and keep the room temperature below 50℃ to prevent the particles from sticking. Please avoid fire and heat sources.

Under normal circumstances, the product is properly stored in the original sealed packaging, and the recommended shelf life is 2 years.

The above suggestions and product information cannot guarantee their completeness, correctness or suitability for special purposes.

Why Choose Us

Customized formula development

Customized formula development

Technical support and testing services

Technical support and testing services

After-sales problem solving

After-sales problem solving

Assist in improving the surface gloss or touch of finished products

Analyze processing abnormalities and provide solutions.

About Us:

|

|

|

|

Dongguan Yiyuan Polymer Materials Co., Ltd. is a company that integrates R&D, production, processing, sales of polymer plastic elastomer materials, plastic modified raw materials, plastic products, and sales of other chemical products (excluding hazardous chemicals): import and export of goods or technology (except for goods and technology import and export prohibited by the state or involving administrative approval).

The company is deeply engaged in professional fields, customer-oriented, and is committed to the modification and solution provision of rubber and plastic raw materials. It advocates reducing the burden on the earth and promoting the recycling of environmentally friendly new materials. Yiyuan provides customers with raw material application technology services, including raw material testing, formula design, product testing, and solving problems in the raw material application process.

Since its establishment, it has invested in the construction of a technical research and development system and established a testing and analysis laboratory. It has independently developed functional materials such as high-elastic particles, lightweight high-elastic particles, ethylene elastomers, thermoplastic elastomers, spot removers, wear resistant agents, shock-absorbing masterbatches, shrinkage stoppers, GRS certified materials, and bio-based certified materials.