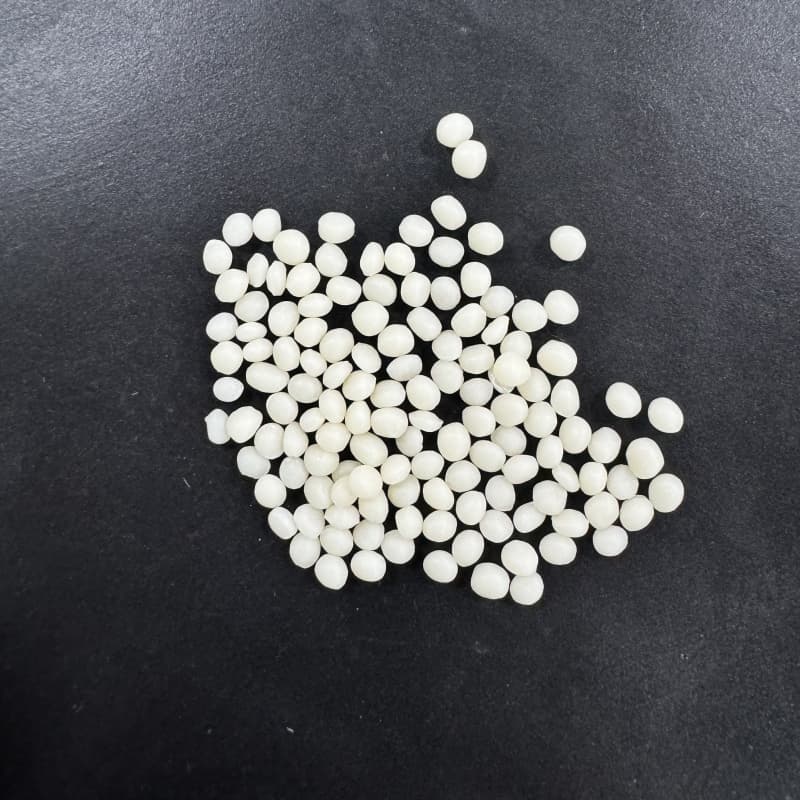

Rubber anti-cracking agent (rubber anti-ozonant) is a high-performance chemical additive designed to significantly enhance the anti-cracking properties of rubber products. By effectively mitigating damage caused by ozone exposure, flex fatigue, and other aging factors, this additive helps maintain the structural integrity and elasticity of rubber, ensuring long-lasting durability in demanding environments.

In addition to its superior anti-ozone properties, our rubber anti-cracking agent improves resistance to weathering, chemical corrosion, and mechanical wear. Its compatibility with various rubber compounds, including natural rubber (NR), styrene-butadiene rubber (SBR), and ethylene-propylene-diene monomer (EPDM), makes it a versatile solution for multiple industrial applications.

This advanced formulation acts as a protective shield, preventing surface cracks and material degradation that typically occur due to prolonged UV exposure, oxidation, and dynamic stress. It is particularly beneficial for rubber products subjected to constant movement, temperature fluctuations, or outdoor conditions, such as tires, seals, hoses, and industrial belts.

Excellent Ozone Resistance: Our rubber anti-cracking agent exhibits outstanding ozone resistance, significantly reducing ozone erosion on rubber products. It forms a protective molecular layer that effectively prevents ozone cracking, even under prolonged exposure to high ozone concentrations.

Superior Flex Fatigue Protection: Our anti-cracking agent enhances the rubber’s resistance to flex fatigue, allowing it to withstand constant deformation without cracking. This is particularly critical for dynamic applications such as tires, conveyor belts, and vibration dampers, where long-term durability is essential.

Excellent Compatibility & Versatility: Designed for broad applicability, our anti-cracking agent ican be widely used in natural rubber and various synthetic rubbers, ensuring consistent performance across different formulations.

Application Scenarios:

Automotive Tire Components

Primarily used in tread rubber for car, truck and bus tires. Enhances durability against road friction and ozone exposure in all-season conditions.

Two-Wheeler Tires

Essential for motorcycle and e-bike tires. Provides superior flex fatigue resistance during frequent acceleration and braking cycles.

Industrial Belting Systems

Critical component in transmission belts and conveyor belts. Protects against mechanical stress in continuous operation environments.

Footwear Components

Key additive for rubber soles and footwear. Improves wear resistance and prevents cracking from repeated flexing.

Usage:

According to the formula and production process of rubber products, mix the appropriate amount of rubber anti-cracking agent evenly into the rubber.

The general dosage depends on the specific product and requirements.

Why Choose Us

Customized formula development

Customized formula development

Technical support and testing services

Technical support and testing services

After-sales problem solving

After-sales problem solving

Assist in improving the surface gloss or touch of finished products

Analyze processing abnormalities and provide solutions.

About Us:

|

|

|

|

Dongguan Yiyuan Polymer Materials Co., Ltd. is a company that integrates R&D, production, processing, sales of polymer plastic elastomer materials, plastic modified raw materials, plastic products, and sales of other chemical products (excluding hazardous chemicals): import and export of goods or technology (except for goods and technology import and export prohibited by the state or involving administrative approval).

The company is deeply engaged in professional fields, customer-oriented, and is committed to the modification and solution provision of rubber and plastic raw materials. It advocates reducing the burden on the earth and promoting the recycling of environmentally friendly new materials. Yiyuan provides customers with raw material application technology services, including raw material testing, formula design, product testing, and solving problems in the raw material application process.

Since its establishment, it has invested in the construction of a technical research and development system and established a testing and analysis laboratory. It has independently developed functional materials such as high-elastic particles, lightweight high-elastic particles, ethylene elastomers, thermoplastic elastomers, spot removers, wear resistant agents, shock-absorbing masterbatches, shrinkage stoppers, GRS certified materials, and bio-based certified materials.