Oil-resistant foaming masterbatch is a functional masterbatch product that is specially formulated and prepared. It uses a specific high molecular polymer as a carrier, and adds a variety of auxiliaries and additives that can enhance oil resistance, optimize foaming performance, and provide other necessary functions. It aims to give foamed products excellent oil resistance and good foaming effect, and meet the needs of various fields for oil-resistant and foaming plastic products.

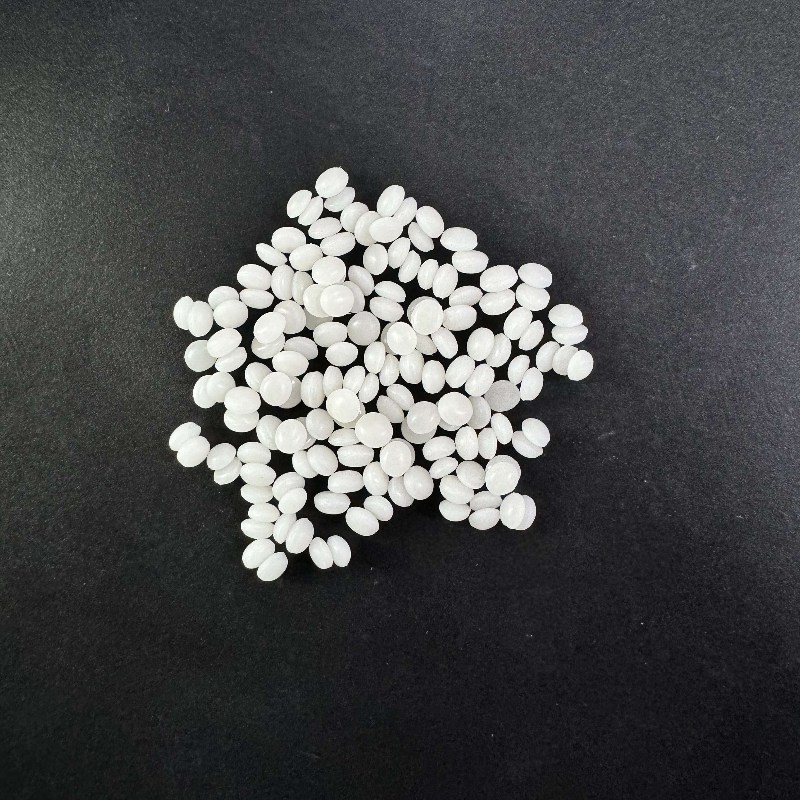

Appearance :

White uniform granulesExperimental Data:

| Property | Typical Value | Test Method / Standard |

| Appearance | White pellet | Visual Inspection |

| Carrier Resin | EVA or compatible polyolefin | / |

| Foaming Performance | Stable, uniform cellular structure | Internal Lab Test |

| Oil Resistance | Excellent – Resistant to Isooctane and 903 oil | Immersion Test |

| Volume Swelling Ratio | ≤ 6% (after 24h in Isooctane) | ISO / Internal Standard |

| Processing Temperature | 150°C – 180°C | Recommended |

| Compatibility | High compatibility with EVA resins | / |

| Dispersion | Uniform, no agglomeration | Visual / Microscopic Analysis |

| Recommended Dosage | 5%–15% (depending on product requirements) | Customer-specific Adjustment |

| Foaming Method | Compression Molding / Injection Molding | / |

| Application Fields | Shoe soles (kitchen, mining, oil station footwear) | / |

| Storage Conditions | Store in a cool, dry place away from sunlight | / |

| Shelf Life | 12 months in unopened condition | / |

Conclusion:

Excellent oil resistance: It can effectively resist the erosion of isooctane and 903 grease. When in contact with oily substances, it maintains stable physical and chemical properties, does not cause swelling, deformation, performance degradation and other problems, and ensures the long-term reliability of the product in the oil environment.

Processing performance: It has good compatibility with EVA resin, is easy to disperse evenly during processing, is suitable for molding and injection foaming processes, and is convenient for producing foam products of various shapes and specifications.

Oil resistance: After the test piece is immersed in isooctane oil for 24 hours, the volume expansion coefficient does not exceed 6%. The international standard is that it is qualified within 12%.

Applicable in other molded foam products where oil exposure is a concern, offering extended product life and reduced maintenance.

Application Scenarios:

This masterbatch is specifically engineered for use in applications that require both foaming and oil resistance.

Typical use cases include:

Shoe Soles for Industrial and Workplace Settings

Ideal for manufacturing oil-resistant soles for:

Kitchen footwear (anti-slip and oil-repellent)

Mining boots (durable and impact-absorbing)

Gas station and factory shoes (resistant to fuel and grease exposure)

Usage method:

Mix ratio: According to the durability and physical performance requirements of the specific foamed sole and the production process, mix the oil-resistant foaming masterbatch with the basic EVA resin in an appropriate ratio.

Why Choos Us

Customized formula development

Customized formula development

Technical support and testing services

Technical support and testing services

After-sales problem solving

After-sales problem solving

Assist in improving the surface gloss or touch of finished products

Analyze processing abnormalities and provide solutions.

About Us:

|

|

|

|

Dongguan Yiyuan Polymer Materials Co., Ltd. is a company that integrates R&D, production, processing, sales of polymer plastic elastomer materials, plastic modified raw materials, plastic products, and sales of other chemical products (excluding hazardous chemicals): import and export of goods or technology (except for goods and technology import and export prohibited by the state or involving administrative approval).

The company is deeply engaged in professional fields, customer-oriented, and is committed to the modification and solution provision of rubber and plastic raw materials. It advocates reducing the burden on the earth and promoting the recycling of environmentally friendly new materials. Yiyuan provides customers with raw material application technology services, including raw material testing, formula design, product testing, and solving problems in the raw material application process.

Since its establishment, it has invested in the construction of a technical research and development system and established a testing and analysis laboratory. It has independently developed functional materials such as high-elastic particles, lightweight high-elastic particles, ethylene elastomers, thermoplastic elastomers, spot removers, wear resistant agents, shock-absorbing masterbatches, shrinkage stoppers, GRS certified materials, and bio-based certified materials.